Plenty of work over the last few weeks.

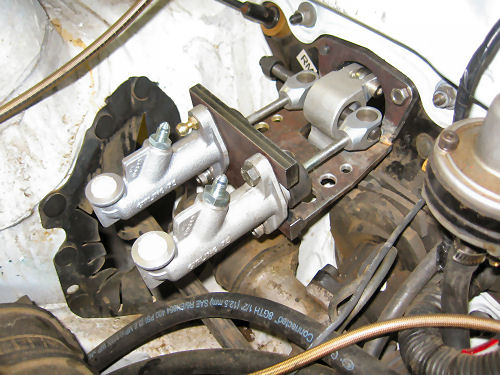

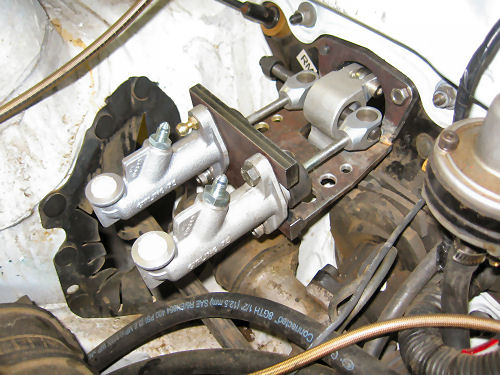

I have now fabricated the Pedalbox That had to miss my Lexmal Ram Induction manifold I bought off ebay. The manifold is off a left hand drive Calibra so couldn't use the standard brake setup thus I had to angle it down to clear the T/Body.

All to do will be tidying it up and painting it... then I can plumb it in and start working out the pedal balance.

Finished the Pedal Box setup. All to do is bleed the brakes and test.

On completeing the pedalbox setup and the Lexmal manifold I finished off a few other things.

The cable adjuster supplied with the ballance bar by Tim from TJM worked well (From the UK)... but I couldn't get a more direct line to the balance bar because with my radical design it was very close to the firewall... where with the normal Mk2 "off the shelf" pedalbox it is easier for more of an arc to run the cable.

So to fix my problem... and note it did work fine but I wanted a better feel and because of the tight radius I needed the cable had a "wind up" feeling to it.

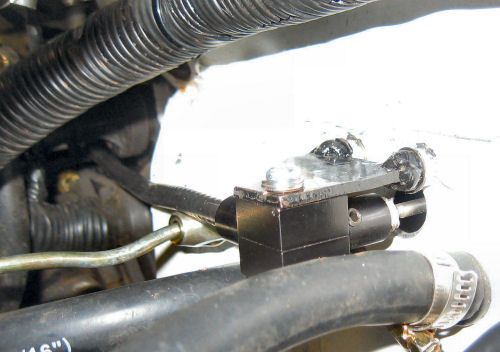

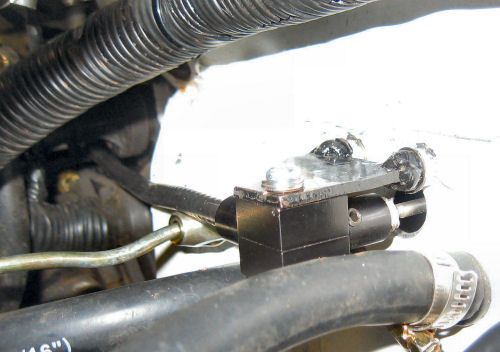

I bought a Tilton 90 deg drive and this made it easier to get the sharp angle I needed.

This gave me great feel at the nob.

The second thing I did was setup my battery isolation switch wich as by the CAMS rules here in Australia there has to be a secondary remote switch at the "A" pilor on the outside of the car.

You can see in the Dash pic above I mounted it in the console where the open tray is under the ash tray.

people seem to wire these up buy running all the wires back into the cab or picking the main power wires out of the wiring loom.

I didn't wanty to do this so I setup a second Isolation Post with extra power connections from a Fishing and Marine Centre. Placing this in the engine bay I connected all the power wires that normaly went to the battery including the Starter/Alternator wire.

then just ran 2 heavy power cable from the isolation switch to the battery and the isolation post and it is all done.

... and here I placed the Pull cable for the battery isolation switch.

I have done a few kms on the road with the new pedal box. This I am very happy with... now to be honest my original brakes where outstanding and if it wasn't for Lexmal manifold I would most likely have not bothered with the pedalbox setup. Now it is done though i am very happy... the brake feel is fantastic and I have full adjustment from locking up the fronts to locking up the rears and all that in between.

You do have to push harder but not as hard as you think... i find it is that first pedal push you notice that there is no vacuume advantage helping you but as soon as you push that little more it all works as expected.

In the end I am running a 0.825" on the front and a 0.75" on the rear. Originaly I was using a 1" Honda Pelude master cylinder. Now this is all depending on you calipers so don't take my sizes as a starting point... find someone who has done this with similar calipers as mine are Astra Mk3 non ABS rear caliper and Holdern Comodore VL Turbo single piston caliper on the front (these are a all alloy finned caliper).

I modified the pedal ratio to 6.0:1 and may increase it a little more... but the more I increase the ratio the more movement I got before the pedal "took up"... I have noticed looking around that 6.2:1 ratio is the recomended starting point.

I am yet to go to the track and test this setup but I am confident this will work as expected.

Finished!

The manifold sounds great... has a deeper throaty sound now and although I havn't given it any stick.. it seems to pull harder down low.

I have a little work to do to get the pedal feel perfect... but I am just happy to get it together again. :Banane44:

Next: 272deg Cam shafts will be next... fitting the cams next week.