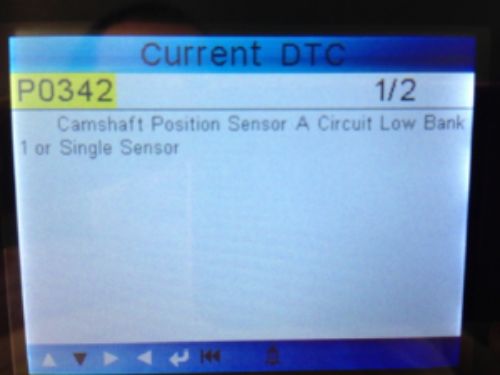

P0342 Cam Signal Fault

Explain how the sensor works and what it does

Explain the components that make up the system, and common problem areas

Explain the common symptoms associated with a system that is not operating per spec

Explain how to diagnose the system, and isolate the problem.

Tools needed for the repair.

CAM POSITION SENSOR The sensor is a simple hall effect sensor mounted in-between the intake and exhaust cam shaft sprockets. The sensor provides the ECM (engine computer) with a signal so the ECM can identify the position of each intake valve (open or closed), so that it may fire each respective injector on the intake stroke. This is called Sequential Fuel Injection, and the CMP (cam position sensor) is a detrimental component required for correct system operation. The sensor communicates with the ECM through it's three prong connector which contains 3 wires, and this is basically the make up of the entire system. Before just replacing a part you should make sure the other components are ok, and the wiring between them. In this case the CMP, the ECM, and the wiring between the two. The CMP connector is a common trouble area. It is plastic and gets brittle with age, and tends to break off the locks located on each side. This causes a loose connection due to engine vibration during operation, causing an intermittent fault, and a CEL with a respective trouble code. The wiring is also a common problem area. The insulation tends to become hard and brittle with age, and flake off. This is called Chafing in the automotive industry, and causes all kinds of crazy intermittent faults, and false diagnosis. If you see below, my vehicle suffers from both, a broken lock, AND wire chafing on the 5 Volt reference signal. THIS MUST BE ADDRESSED...

Notice the wires, and the one all on the right how it is exposed, and looks weathered and beat up. While it is not broken, and my signals were all to spec, I'm still going to repair the connector to prevent future problems.

Wire definitions (left ot right):

Red/White (Battery +)

Black (system ground)

Brown/White (Cam signal/5volt reference)

What happens when P0342 sets:

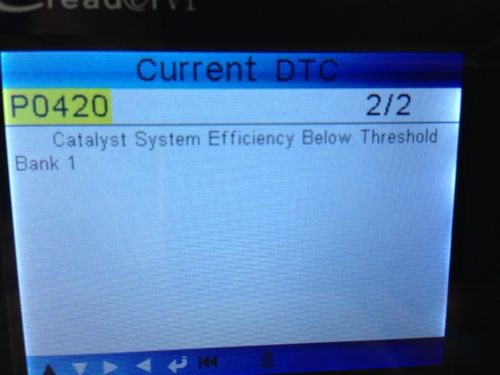

The computer lights the CEL, ignores the cam single, and fires the injectors based on a fixed algorithm it references using the crank position sensor. This causes a richer than normal mixture in the engine which in turn affects the performance and efficiency of your engine. You can expect a higher than normal fuel consumption, a rough, or lumpy idle, rich smell from the exhaust, sluggish low speed performance, and affected catalyst performance. Usually P0342 will cause catalyst, as well as fuel related DTC's to set conjointly. Also extended neglect can cause permanent damage to your catalyst, as it is not designed to handle extended rich mixtures in the exhaust. My car set both 0342/and 420 see below.

Since we know that the CMP is detrimental in controlling the fuel mixture being fed into the engine, and we know if a problem with the circuit presents itself, the engine will run richer, we shall focus our attention on P0342 for the moment, because there is a high chance that correcting the issue, will correct the P0420 as well.

Next post testing the system voltage/signal voltage....